Today, I continued with the process of building my bamboo rod. My start point today was with the 16 pieces that I had done the initial beveling to get to a triangular shape. The first step was to send the pieces through the beveler to get closer to the final dimensions. We took off about .03 of an inch with each pass.

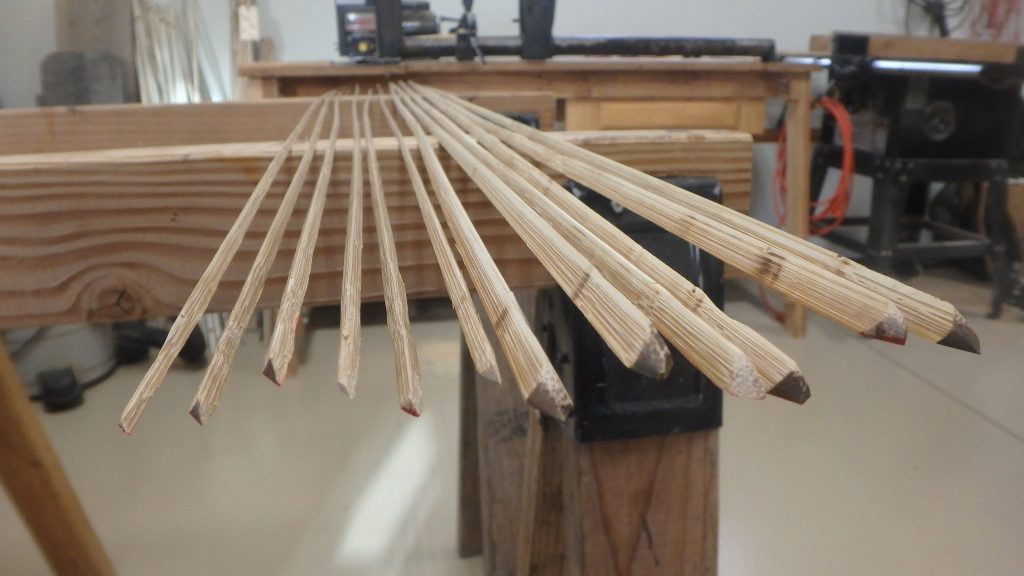

At this point I picked the final 12 split pieces of bamboo from my initial 18 . I choose 6 from each culm – my choice selection was a mix of the look of each split and how straight it was. 3 pieces from each culm will make up the butt and tip sections. I set the other four to the side – just in case!

Next step up – bevel in a rough taper into the final 12 pieces.

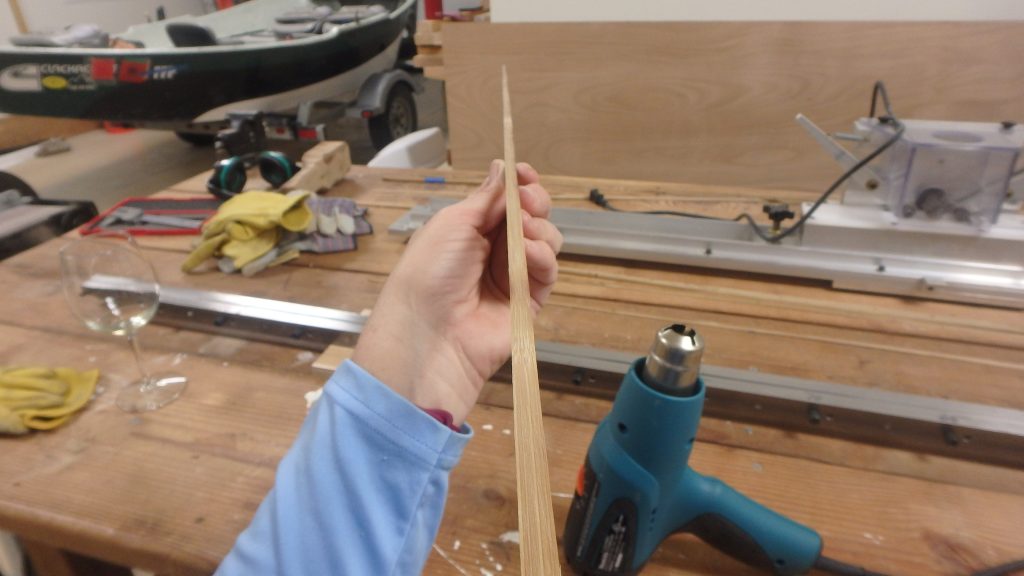

The next step was to straighten each strip of bamboo. Straightening the bamboo at this point will enable the hand planing process to be smoother and more precise. To get the bend out of the bamboo you bend the rod in the opposite direction over a heat – until the bend has been removed.

All twelve pieces ready for the hand planing process. You can see the difference is the size for the butt versus the tip section

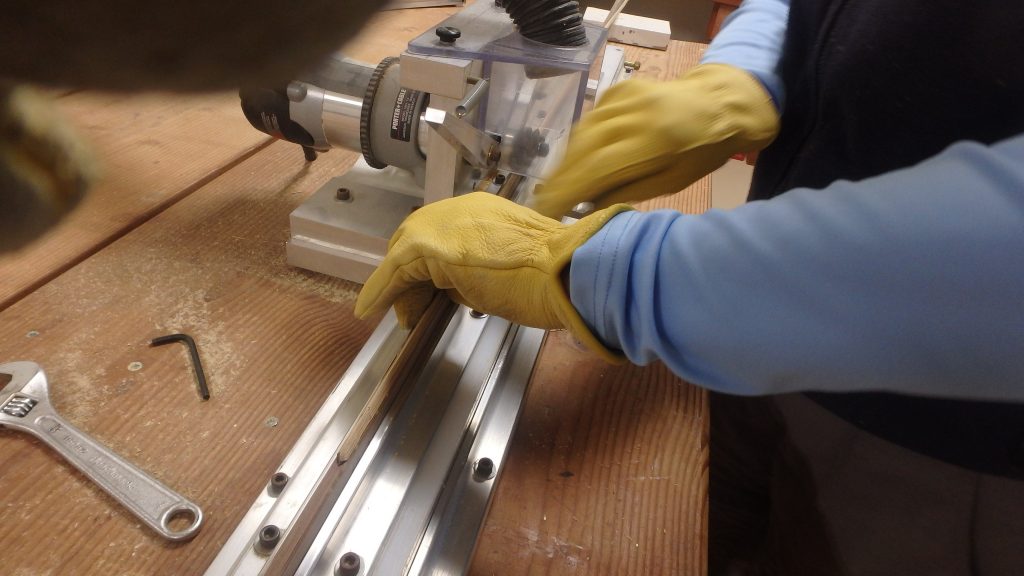

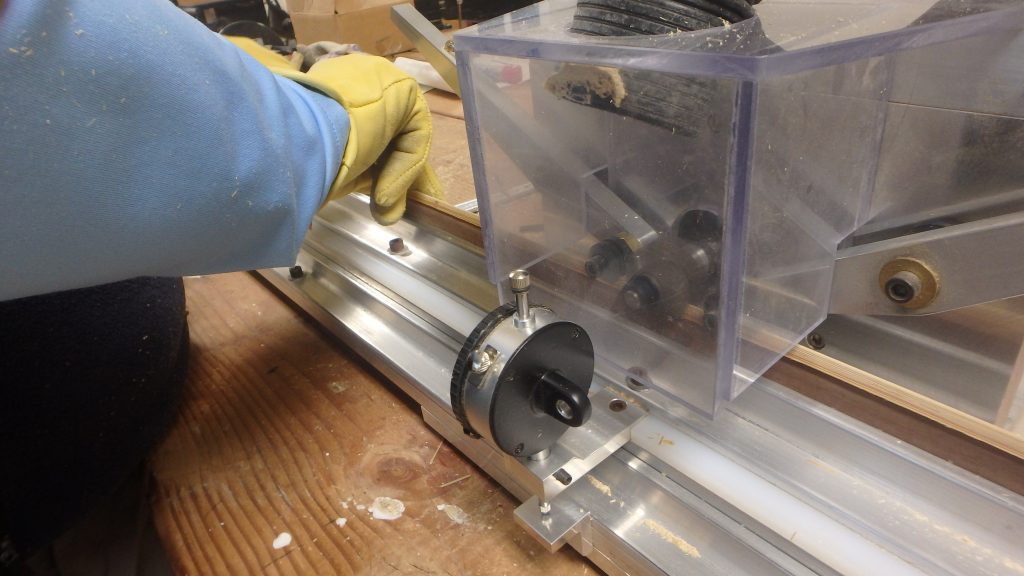

Next step – setting the depth on the planing form to create the desired taper for my 8′ 6 wt rod. Accuracy is key with this step – so I did double check my settings and then Dave checked me. We set the specific taper depth at every 5″ mark – the depth for the tip section started at .104″ and ended at .028″

Today – I just got started on the hand planing process. I anticipate it will take me about 4 to 6 hours to plane all the strips.

Comments are closed